Understanding Pressure Swing Adsorption Technology for Nitrogen Generation

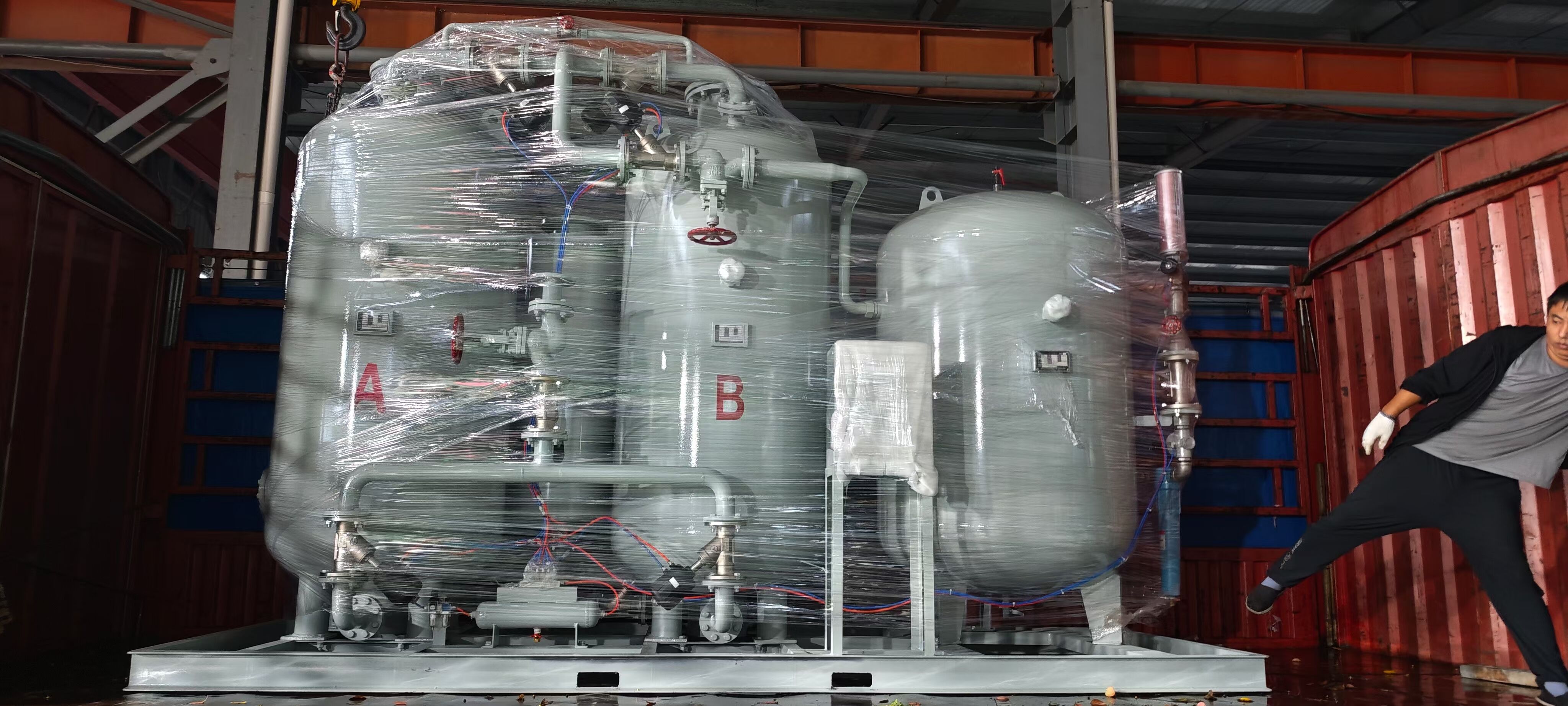

In today's industrial landscape, the demand for reliable and efficient nitrogen generation solutions continues to grow. Pressure Swing Adsorption (PSA) nitrogen generation has emerged as a revolutionary technology that transforms how industries access and utilize nitrogen gas. This advanced system separates nitrogen from compressed air using specialized molecular sieve materials, delivering high-purity nitrogen gas for various applications.

The PSA nitrogen generation process represents a significant leap forward from traditional nitrogen supply methods. By eliminating the need for delivered liquid nitrogen and high-pressure cylinders, organizations can achieve greater operational control while reducing their environmental impact and costs. Let's explore the compelling advantages that make PSA nitrogen systems an indispensable asset for modern industrial operations.

Economic Advantages of On-Site PSA Nitrogen Generation

Substantial Cost Reduction Through Self-Sufficient Production

Implementing a PSA nitrogen generation system delivers immediate and long-term financial benefits. The initial investment in PSA technology typically yields returns within 12-24 months through eliminated delivery charges, rental fees, and price fluctuations associated with traditional nitrogen supply methods. Organizations can achieve cost savings of up to 40-80% compared to liquid nitrogen delivery or cylinder packages.

Operating costs remain predictable and manageable, primarily consisting of electricity consumption and minimal maintenance requirements. This predictability allows for better budget planning and resource allocation, making PSA nitrogen an economically sustainable solution for businesses of all sizes.

Elimination of Supply Chain Dependencies

On-site PSA nitrogen generation provides freedom from complex supply chain logistics and potential disruptions. Companies no longer need to coordinate deliveries, manage inventory levels, or worry about supplier reliability. This independence proves particularly valuable during periods of market volatility or when operating in remote locations where traditional nitrogen supply may be challenging or costly to maintain.

The self-sufficient nature of PSA systems also eliminates hidden costs such as delivery surcharges, hazmat fees, and emergency delivery premiums that often accompany traditional nitrogen supply methods. This streamlined approach to nitrogen generation translates into improved operational efficiency and reduced administrative overhead.

Operational Excellence and Reliability

Continuous Supply Guarantee

PSA nitrogen systems operate continuously, providing an uninterrupted supply of nitrogen gas whenever needed. This constant availability eliminates production delays and downtime associated with waiting for nitrogen deliveries or cylinder replacements. The technology's robust design and redundant safety features ensure reliable performance, with system uptimes typically exceeding 98%.

Modern PSA nitrogen generators incorporate advanced monitoring systems that provide real-time performance data and predictive maintenance alerts. This proactive approach to system management helps prevent unexpected shutdowns and ensures optimal operation throughout the equipment's lifecycle.

Customizable Purity Levels

PSA nitrogen technology offers remarkable flexibility in nitrogen purity levels, typically ranging from 95% to 99.999%, depending on application requirements. This adaptability allows organizations to precisely match nitrogen purity to their specific needs, avoiding unnecessary energy consumption from generating higher-purity nitrogen than required.

The ability to adjust purity levels on-demand provides operational flexibility and cost optimization opportunities. Industries can fine-tune their nitrogen generation parameters based on evolving production requirements or different applications within the same facility.

Environmental and Safety Benefits

Reduced Carbon Footprint

PSA nitrogen generation significantly reduces the environmental impact compared to traditional nitrogen supply methods. By eliminating the need for frequent delivery trucks and the energy-intensive process of liquid nitrogen production, organizations can substantially lower their carbon emissions. Studies indicate that on-site PSA nitrogen generation can reduce CO2 emissions by up to 50% compared to delivered liquid nitrogen.

The system's energy efficiency continues to improve with technological advancements, making PSA nitrogen an increasingly sustainable choice for environmentally conscious organizations. The reduced reliance on transportation and packaging materials further contributes to environmental preservation efforts.

Enhanced Workplace Safety

On-site PSA nitrogen systems eliminate many safety risks associated with handling and storing liquid nitrogen or high-pressure cylinders. There's no need for staff to manage heavy cylinders or risk exposure to cryogenic liquids. The automated operation of PSA systems minimizes human intervention and potential accidents.

Modern PSA nitrogen generators feature comprehensive safety systems, including pressure relief valves, oxygen analyzers, and emergency shutdown capabilities. These built-in safeguards provide peace of mind while ensuring compliance with industrial safety standards.

Scalability and Future-Proofing

Modular System Design

PSA nitrogen systems offer excellent scalability through their modular design. Organizations can easily expand their nitrogen generation capacity by adding parallel units or upgrading existing components. This flexibility allows businesses to align their nitrogen production capabilities with growth plans without significant disruption to operations.

The modular approach also facilitates system maintenance and upgrades, as individual components can be serviced or replaced without affecting the entire installation. This design philosophy ensures long-term system viability and adaptability to changing business needs.

Integration with Industry 4.0

Modern PSA nitrogen generators seamlessly integrate with industrial automation and control systems, supporting Industry 4.0 initiatives. Advanced monitoring capabilities provide valuable data for process optimization, predictive maintenance, and energy management. This integration enables smarter decision-making and improved operational efficiency.

The technology's compatibility with digital transformation efforts positions organizations for future success in an increasingly connected industrial environment. Remote monitoring and control capabilities ensure optimal system performance while minimizing the need for on-site personnel.

Frequently Asked Questions

What maintenance does a PSA nitrogen system require?

PSA nitrogen systems require minimal maintenance, typically including regular filter changes, annual valve inspections, and periodic molecular sieve replacement every 5-10 years. Most maintenance tasks can be performed during scheduled downtime, ensuring minimal impact on operations.

How quickly can a PSA nitrogen system achieve ROI?

Return on investment for PSA nitrogen systems typically occurs within 12-24 months, depending on current nitrogen usage and costs. Facilities with high nitrogen consumption often see faster payback periods, sometimes as short as 6-8 months.

What factors affect PSA nitrogen purity levels?

Several factors influence nitrogen purity in PSA systems, including inlet air quality, operating pressure, cycle time settings, and molecular sieve condition. Modern systems automatically adjust these parameters to maintain desired purity levels while optimizing energy efficiency.

Can PSA nitrogen systems operate in extreme environments?

PSA nitrogen systems are designed to operate effectively across a wide range of environmental conditions. With proper installation and protection measures, these systems can function reliably in both hot and cold climates, though extreme conditions may require additional environmental controls or specialized system configurations.