The principle of any PSA nitrogen generator appears simple: use a filter to separate nitrogen from the air. But the quality, durability, and nature of that "filter"—the Carbon Molecular Sieve (CMS)—is the single most critical factor that separates an average, inefficient system from a superior, highly profitable one. It is, quite literally, the heart of the machine. Understanding its role is key to making a smart investment.

How PSA Technology Leverages CMS for Nitrogen Separation

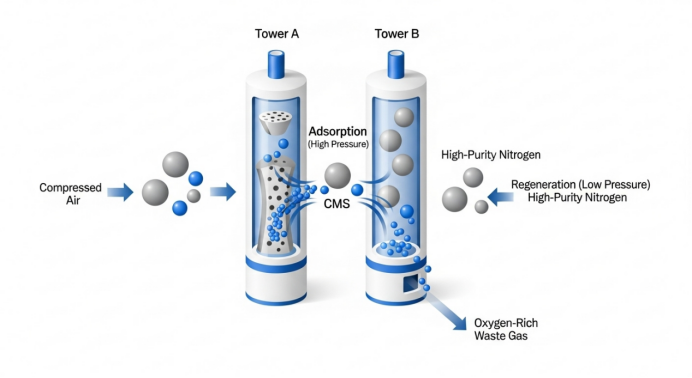

PSA (Pressure Swing Adsorption) technology is an ingenious process that leverages the unique properties of CMS. Here’s a step-by-step breakdown:

The Process in Three Simple Steps:

The Three Ways a Superior CMS Directly Impacts Your Bottom Line

A high-performance CMS doesn't just produce nitrogen; it drives profitability. Here are the three core benefits a superior CMS delivers:

1. It Defines Your System's Efficiency (and Energy Bill)

A high-performance CMS requires less compressed air to produce the same amount of nitrogen—a metric known as the "air factor." A lower air factor means you need a smaller, less power-hungry air compressor, directly slashing your long-term electricity costs and potentially reducing your initial capital investment.

2. It Determines Your System's Lifespan (and Reliability)

A durable CMS must withstand millions of high-pressure cycles. Low-quality CMS can pulverize into dust, clogging valves and causing catastrophic failures. A robust CMS, engineered for high mechanical strength, ensures a service life of over 10 years, protecting your investment and guaranteeing the uninterrupted reliability of your production line.

3. It Dictates Your System's Size (and Footprint)

Because a more efficient CMS can process more air in a smaller volume, it allows for a more compact system design. This means smaller adsorption towers and a reduced overall footprint, saving valuable floor space in your facility and contributing to a better Quality-to-Cost Ratio.

Conclusion: Choosing the Right System Starts with Understanding the Core

As we've seen, the performance of a PSA nitrogen generator is not just about its valves or controls; it is fundamentally determined by the quality of its Carbon Molecular Sieve. Therefore, choosing a supplier who has a deep, first-hand mastery of this core technology is the most critical decision you can make.

At NitroQuanta, our entire engineering philosophy is built around this principle. Discover how our unique, dual expertise in both CMS science and system engineering results in a superior nitrogen solution.