Pressure Swing Adsorption (PSA) is the leading technology for on-site nitrogen generation, but how does it actually work at a microscopic level? The answer lies in the remarkable properties of its core adsorbent, the Carbon Molecular Sieve (CMS), and a scientific principle known as kinetic separation. This article provides a detailed, theoretical explanation of the PSA working principle.

The Adsorbent: What is Carbon Molecular Sieve?

An Engineered Material for Molecular Sorting

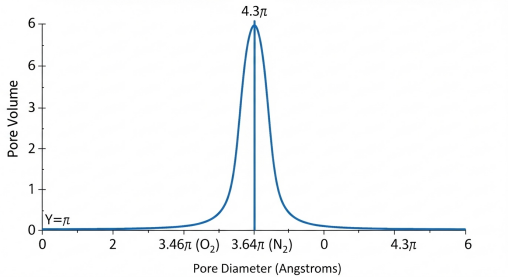

Carbon Molecular Sieve (CMS) is a specialized, cylindrical pellet adsorbent engineered from precursor resins. Through a meticulous process of grinding, molding, carbonization, and pore structure treatment, we create a material with a vast network of precisely controlled micropores on its surface and within its interior. As the pore distribution diagram below shows, the key to CMS is that its pores are intentionally designed to be in the same order of magnitude as the gas molecules in the air.

The Mechanism: Kinetic Separation Explained

A Race Between Oxygen and Nitrogen Molecules

The primary function of CMS is to separate O₂ and N₂ based on the subtle difference in their kinetic diameters. This is not about chemical reaction, but about speed.

Consequently, when compressed air passes through a CMS bed, oxygen is adsorbed much more quickly and in greater quantity than nitrogen. This leaves the gas phase outside the sieve highly enriched with nitrogen and a smaller amount of argon (which has a diffusion rate slower than oxygen).

The Process: Pressure Swing Adsorption in Action

Leveraging Adsorption Characteristics with Pressure and Time

The kinetic separation effect is powerfully amplified by controlling pressure and time. As the adsorption curves demonstrate, increasing the pressure enhances the adsorption capacity for both gases, but the relative increase is more significant for oxygen.

The "swing" in Pressure Swing Adsorption refers to a rapid, continuous cycle:

By orchestrating this cycle between two alternating towers (or in a single tower design), an automated control system continuously produces a stream of high-purity product nitrogen.

Conclusion: From Theory to Performance

The working principle of a PSA nitrogen generator is a perfect synergy between the microscopic properties of the Carbon Molecular Sieve and the macroscopic engineering of the system. The dynamic adsorption capacity, selectivity, and physical durability of the CMS are what ultimately determine the efficiency, energy consumption, and reliability of the final equipment.

At NitroQuanta, our entire brand philosophy is built upon mastering this science.