high purity nitrogen generator manufacturers

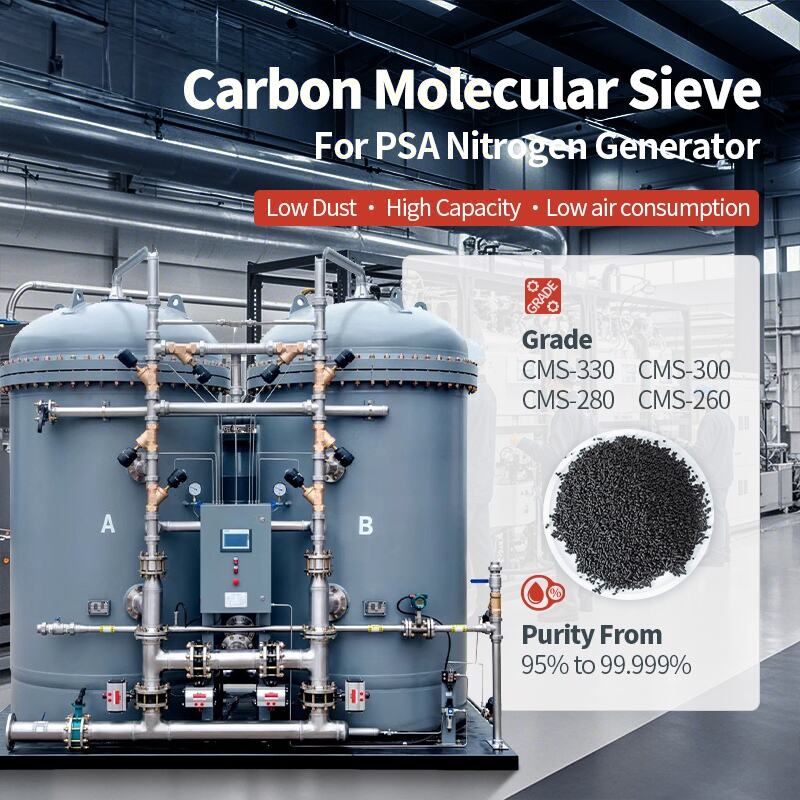

High purity nitrogen generator manufacturers are industry leaders specializing in the development and production of advanced gas separation systems. These manufacturers employ cutting-edge technology to design and build generators that produce nitrogen gas with purity levels reaching up to 99.9999%. Their systems typically utilize Pressure Swing Adsorption (PSA) or membrane separation technology to extract nitrogen from ambient air. The manufacturing process involves rigorous quality control measures and adherence to international standards to ensure consistent product excellence. These manufacturers offer a range of models suitable for various applications, from small laboratory units to large industrial installations. They incorporate smart monitoring systems, automated controls, and energy-efficient components to optimize performance and reliability. The generators are designed with user-friendly interfaces, preventive maintenance alerts, and remote monitoring capabilities. Many manufacturers also provide customization options to meet specific customer requirements, including flow rates, pressure levels, and purity specifications. Their products serve diverse industries including pharmaceuticals, food packaging, electronics manufacturing, and chemical processing. These manufacturers typically offer comprehensive after-sales support, including installation, training, and maintenance services.