nitrogen gas generator manufacturers

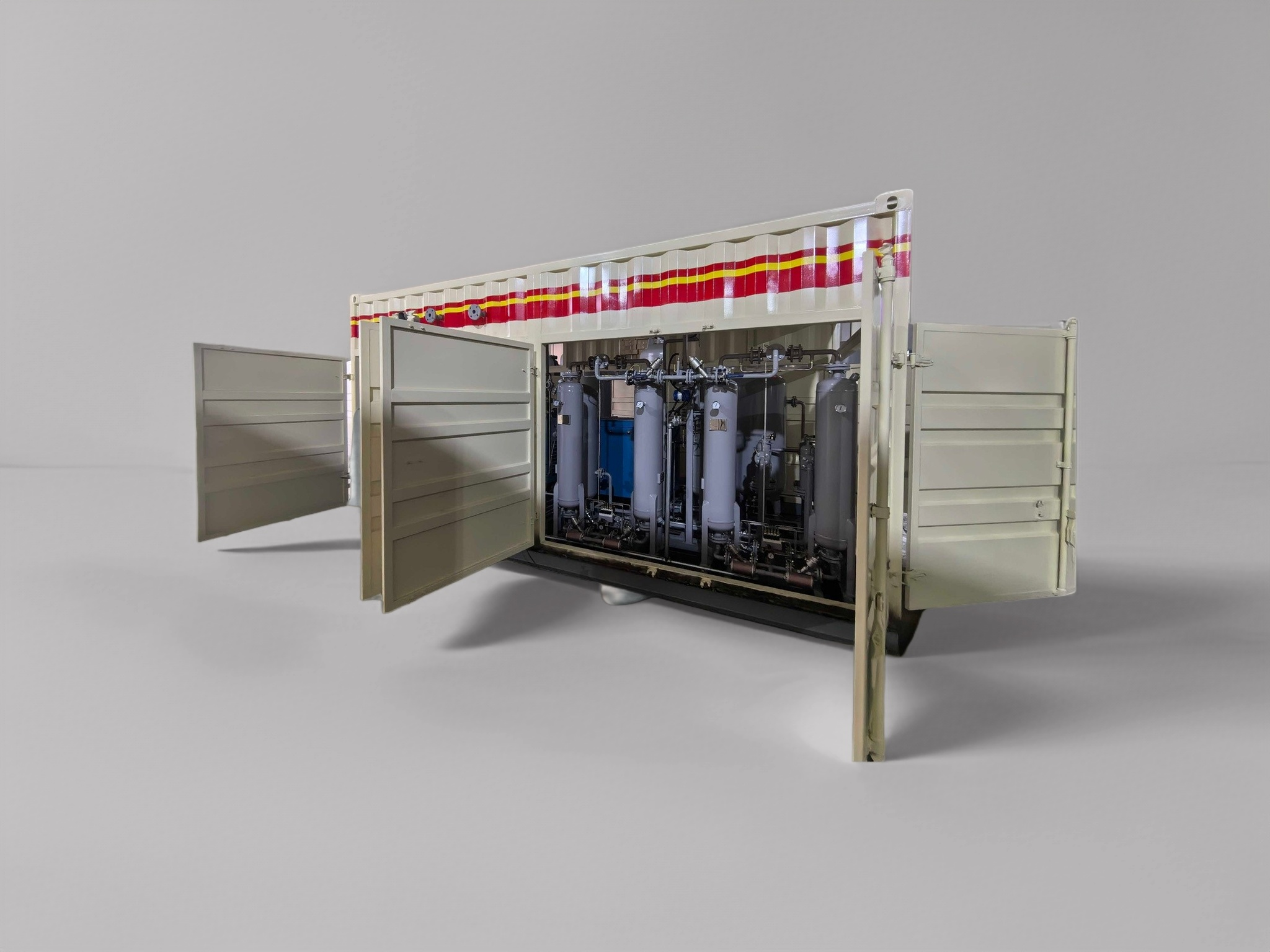

Nitrogen gas generator manufacturers are industry leaders in developing and producing advanced systems that create high purity nitrogen gas on demand. These manufacturers specialize in designing and building reliable equipment that separates nitrogen from ambient air through various technologies, primarily pressure swing adsorption (PSA) or membrane separation methods. Their products serve diverse industries, from pharmaceutical and food packaging to electronics and chemical processing. Modern nitrogen generator manufacturers incorporate smart technology features, including automated monitoring systems, remote operation capabilities, and predictive maintenance algorithms. These systems are engineered to deliver consistent nitrogen purity levels ranging from 95% to 99.999%, depending on specific application requirements. The manufacturers focus on energy efficiency, implementing advanced heat recovery systems and optimized compression cycles to reduce operational costs. They also provide customization options to meet specific flow rates, pressure requirements, and installation constraints. Quality control measures include rigorous testing protocols and compliance with international standards such as ISO 9001, ensuring reliable and safe operation. Many manufacturers offer comprehensive after sales support, including maintenance programs, technical consultation, and spare parts availability.