industrial nitrogen generator manufacturers

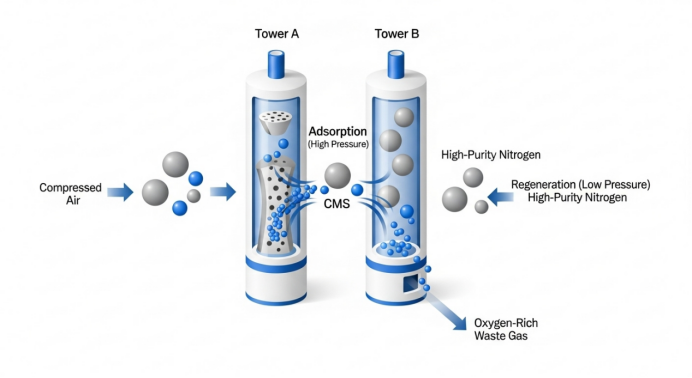

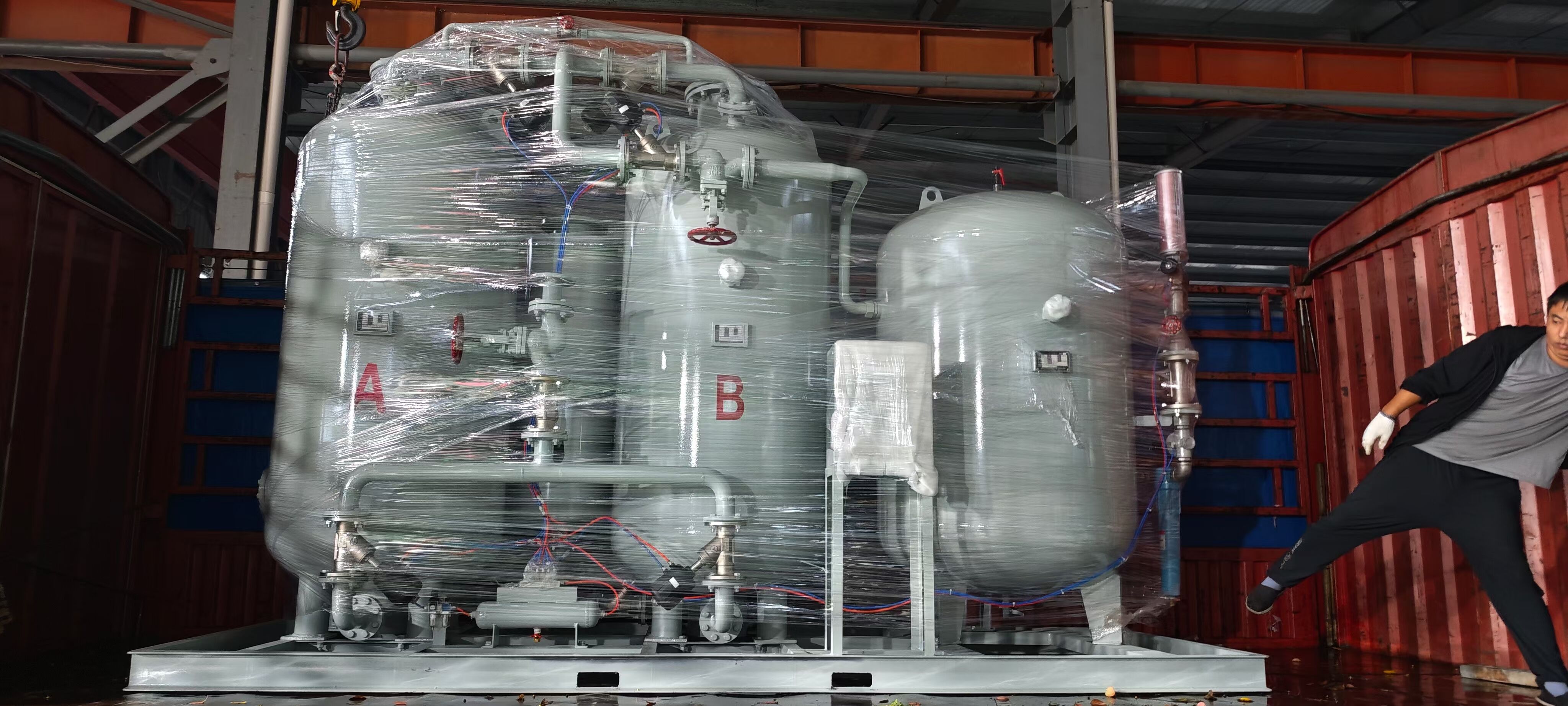

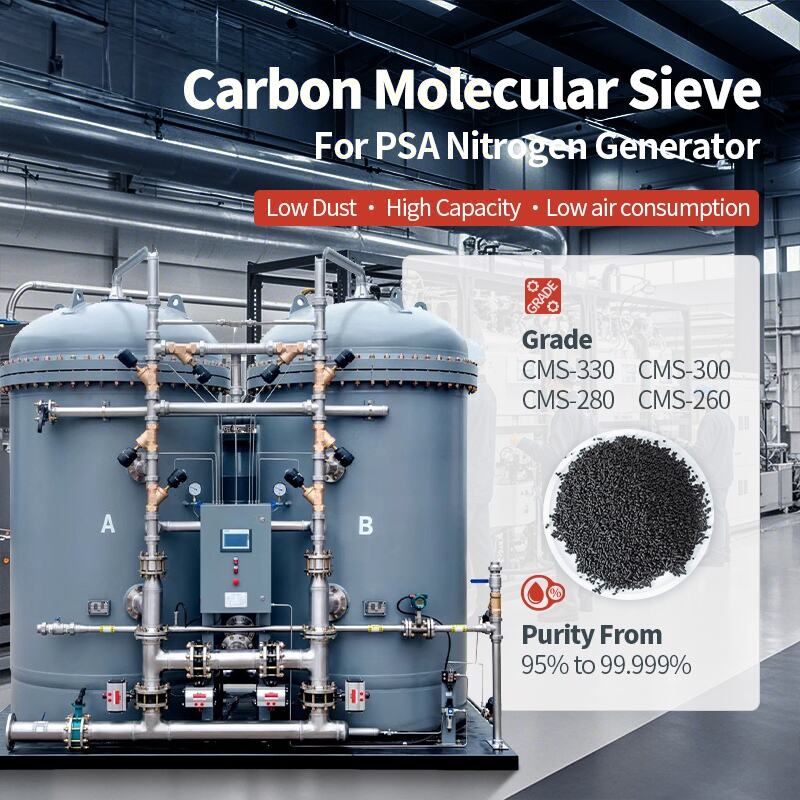

Industrial nitrogen generator manufacturers play a crucial role in modern manufacturing by providing essential equipment that produces high-purity nitrogen gas on-site. These manufacturers design and produce systems that utilize pressure swing adsorption (PSA) or membrane technology to separate nitrogen from atmospheric air. The generators they create can achieve purity levels ranging from 95% to 99.999%, meeting diverse industrial requirements. These manufacturers incorporate advanced monitoring systems, automated controls, and energy-efficient components to ensure reliable operation and optimal performance. Their products serve various industries, including food packaging, electronics manufacturing, pharmaceutical production, and chemical processing. Modern industrial nitrogen generators feature sophisticated filtration systems, precise flow control mechanisms, and robust construction to withstand continuous operation. Manufacturers often provide customizable solutions to meet specific flow rates, pressure requirements, and purity levels. They also integrate smart technology for remote monitoring, preventive maintenance alerts, and performance optimization. These systems are designed with redundancy features and fail-safes to ensure uninterrupted nitrogen supply, crucial for critical applications. Additionally, manufacturers offer comprehensive support services, including installation, maintenance, and technical consultation to ensure optimal system performance throughout its lifecycle.