nitrogen gas provide

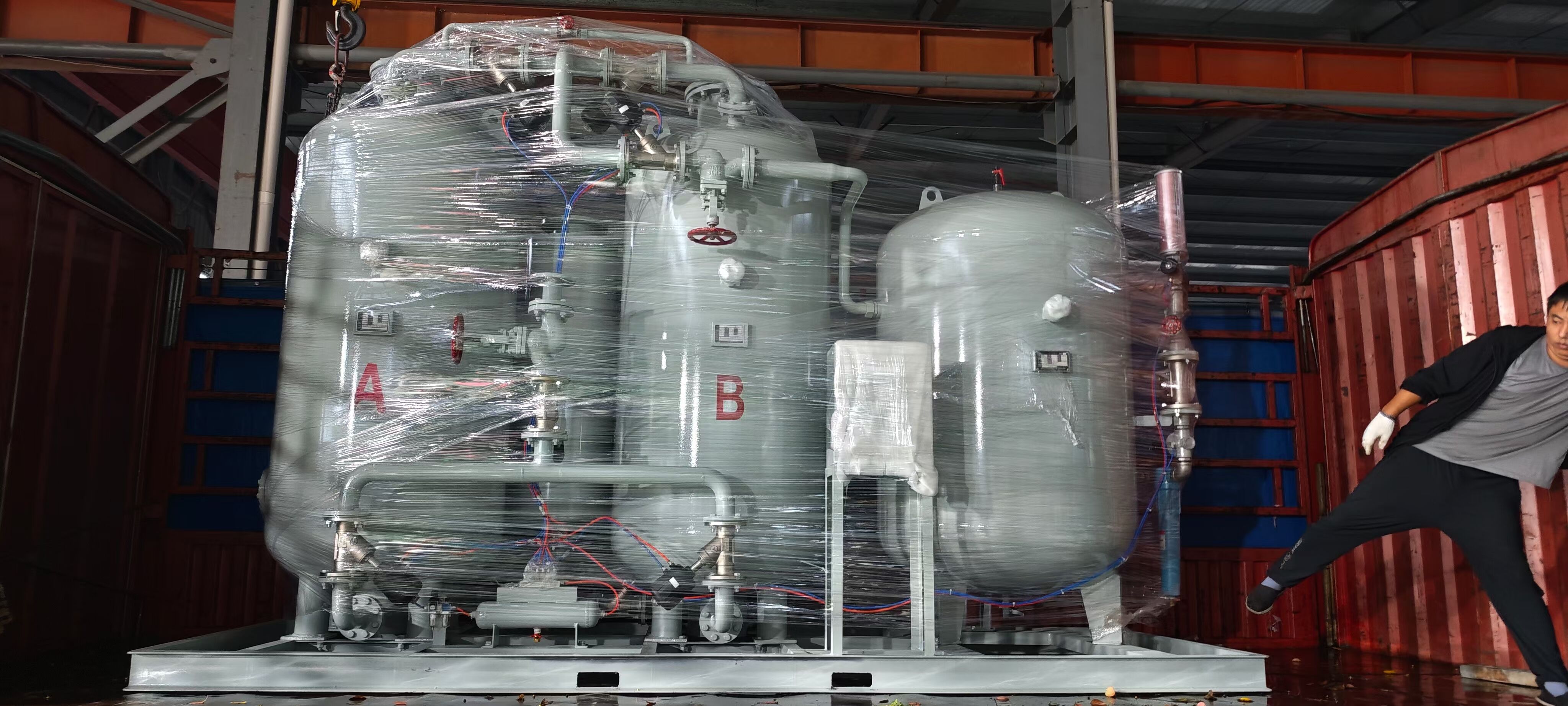

A nitrogen gas provider delivers essential solutions for various industrial applications through advanced gas generation and distribution systems. These systems utilize pressure swing adsorption (PSA) or membrane technology to separate nitrogen from ambient air, providing a reliable and cost-effective source of high-purity nitrogen gas. Modern nitrogen gas providers offer comprehensive solutions that include on-site generation equipment, storage systems, and distribution networks, ensuring consistent supply for critical operations. The systems are designed with sophisticated monitoring capabilities, automated pressure control mechanisms, and redundant safety features to maintain optimal performance and reliability. Applications span across multiple industries, including food packaging, electronics manufacturing, pharmaceutical production, and chemical processing. These providers typically offer customizable solutions that can be scaled according to specific flow rates, purity requirements, and pressure specifications. Additionally, they incorporate smart monitoring systems that enable real-time performance tracking, predictive maintenance scheduling, and remote system diagnostics, ensuring uninterrupted nitrogen supply for mission-critical processes.