nitrogen generator supplier

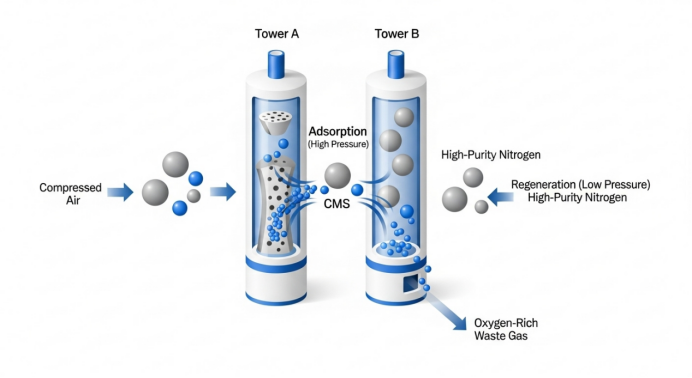

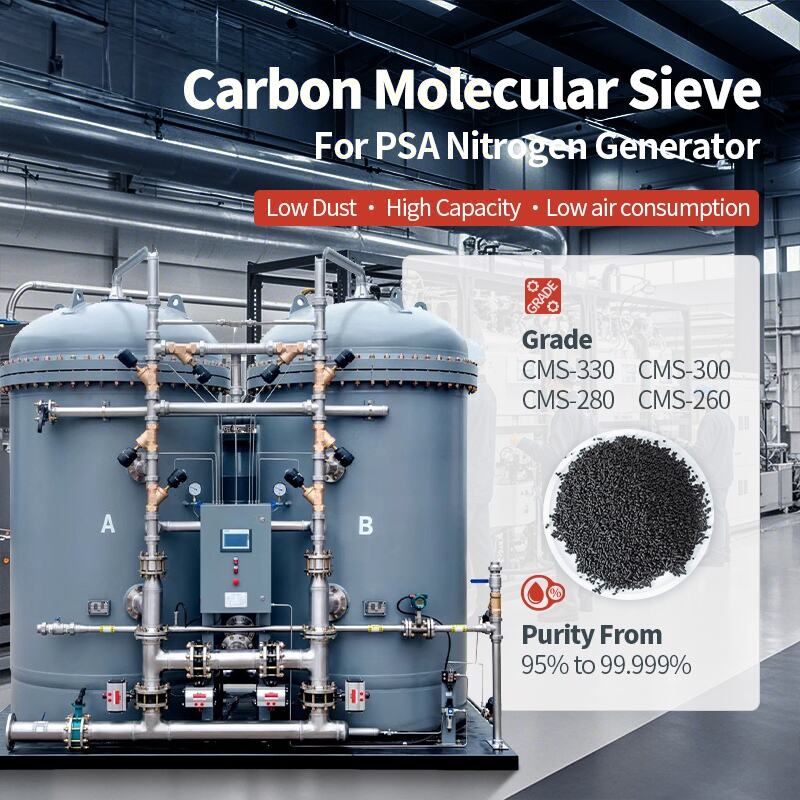

A nitrogen generator supplier stands as a crucial partner in industrial operations, providing essential equipment that produces high-purity nitrogen gas on-site. These suppliers offer comprehensive solutions utilizing pressure swing adsorption (PSA) or membrane technology to separate nitrogen from ambient air. Their systems deliver nitrogen purities ranging from 95% to 99.999%, meeting diverse industry requirements. The supplied generators incorporate advanced filtration systems, precise monitoring equipment, and automated controls to ensure consistent nitrogen production. These suppliers not only provide the physical equipment but also offer extensive technical support, maintenance services, and system optimization guidance. They work closely with clients across various sectors including food packaging, electronics manufacturing, pharmaceutical production, and chemical processing. The systems they supply are designed with energy efficiency in mind, featuring variable flow rates and smart power management. Many suppliers also include remote monitoring capabilities, allowing real-time system performance tracking and predictive maintenance scheduling. Their expertise extends to custom system design, ensuring each solution aligns perfectly with specific application requirements and space constraints.