nitrogen plant suppliers

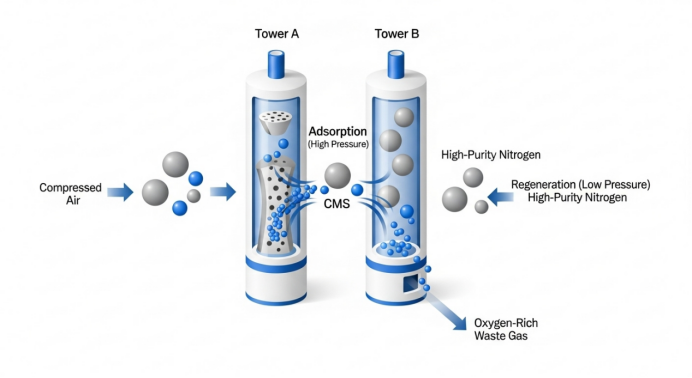

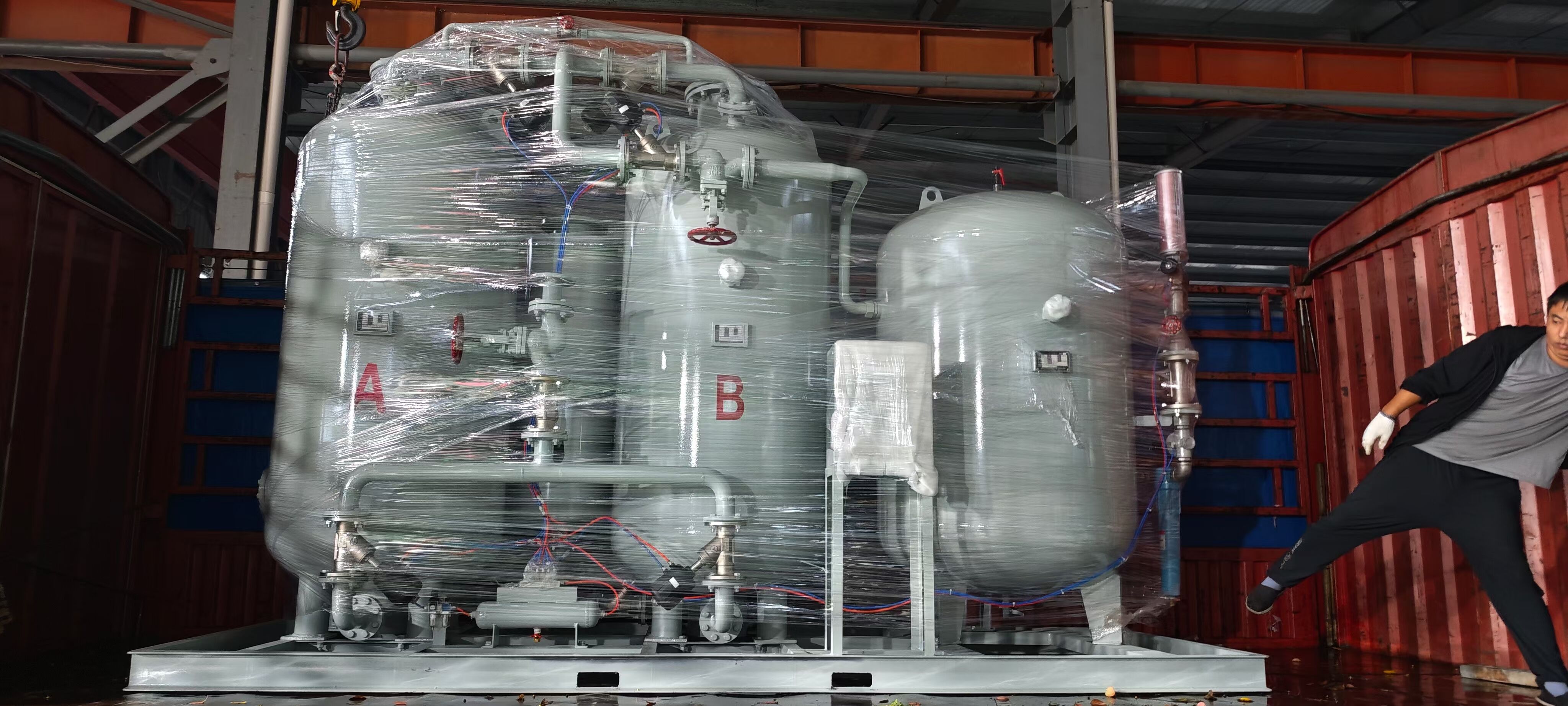

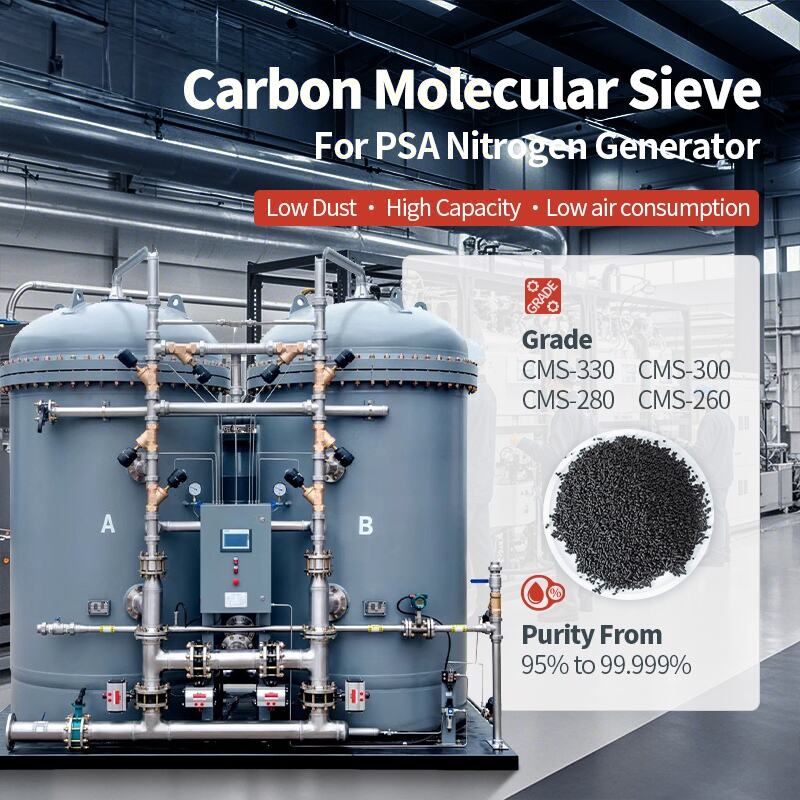

Nitrogen plant suppliers play a crucial role in providing essential gas generation solutions across various industries. These suppliers specialize in designing, manufacturing, and delivering nitrogen generation systems that produce high-purity nitrogen gas through advanced air separation technologies. Modern nitrogen plants utilize sophisticated pressure swing adsorption (PSA) or membrane separation techniques to extract nitrogen from atmospheric air, achieving purity levels up to 99.999%. These systems are engineered to meet specific flow rates, pressure requirements, and purity specifications based on customer needs. The plants come equipped with advanced control systems, monitoring capabilities, and safety features to ensure reliable operation. Suppliers typically offer comprehensive solutions including installation, commissioning, maintenance services, and technical support. These facilities are designed to serve diverse applications across industries including chemical processing, food packaging, electronics manufacturing, pharmaceutical production, and metal treatment. The systems are built to comply with international safety standards and environmental regulations, featuring energy-efficient components and automated operation protocols. Leading suppliers also provide customization options, allowing businesses to scale their nitrogen production capacity according to demand while maintaining optimal operational efficiency.