membrane nitrogen generator manufacturers

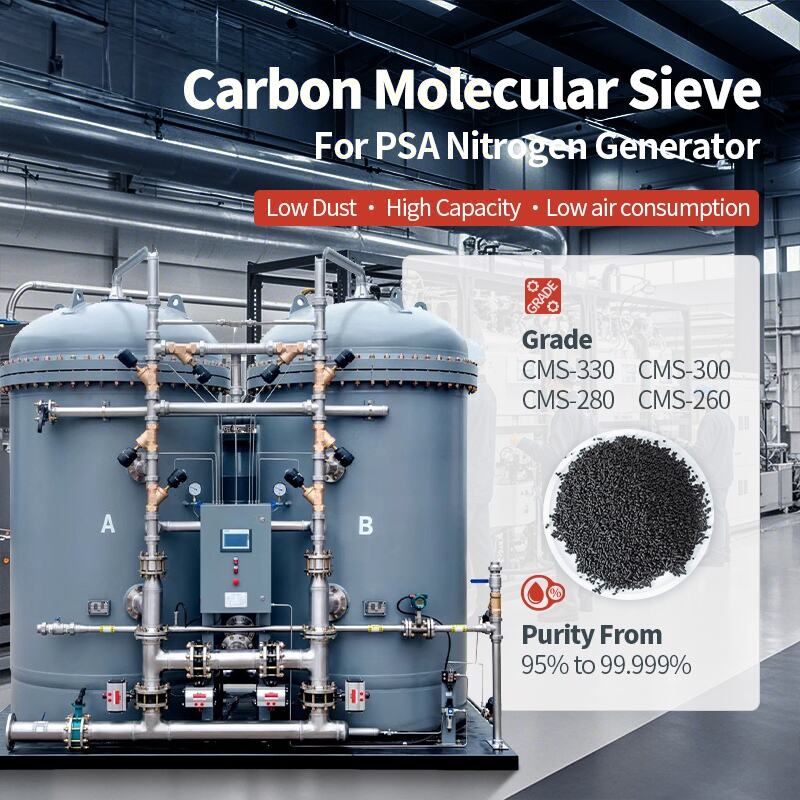

Membrane nitrogen generator manufacturers represent a crucial sector in industrial gas production, specializing in the development and production of advanced separation systems that extract nitrogen from atmospheric air. These manufacturers employ cutting-edge membrane technology that utilizes selective permeation principles to separate nitrogen from other atmospheric gases. Their systems feature hollow fiber membranes with precisely engineered pore sizes that allow smaller molecules like oxygen to pass through while retaining nitrogen. These manufacturers focus on producing systems that deliver consistent purity levels ranging from 95% to 99.999%, catering to various industrial requirements. Their products incorporate sophisticated control systems, automated operation features, and real-time monitoring capabilities to ensure reliable nitrogen production. The manufacturing process involves rigorous quality control measures, including precision membrane assembly, comprehensive testing protocols, and adherence to international safety standards. These manufacturers also provide customization options to meet specific flow rates, pressure requirements, and purity levels. Their systems find applications across diverse industries, including food packaging, electronics manufacturing, pharmaceutical production, and chemical processing. Modern membrane nitrogen generator manufacturers emphasize energy efficiency, minimal maintenance requirements, and environmental sustainability in their design approaches.