Key Applications & Technical Details

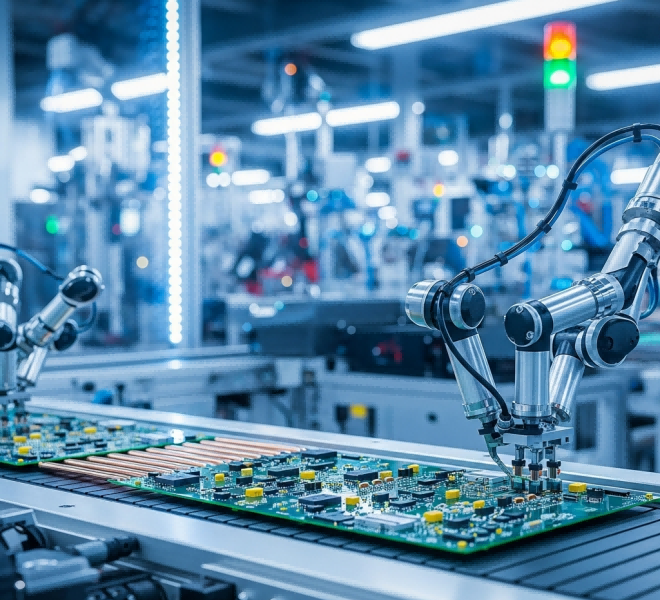

SMT Reflow Soldering: In this process, nitrogen gas (typically at a purity of 99.9% to 99.95%, or 500-1000 ppm O₂) is introduced into the preheating, soldering, and cooling zones of the reflow oven to create a low-oxygen atmosphere. The key benefits are:

1. Reduced Oxidation: Drastically minimizes the oxidation of PCB pads, component leads, and molten solder, thereby improving solderability.

2. Fewer Soldering Defects: Lowers the surface tension of the solder, enhancing its wetting and flow characteristics. This significantly reduces microscopic defects such as BGA voiding, solder balling, and bridging.

3. Significant Dross Reduction: Reduces the formation of dross (solder oxide) by 80-90%, leading to considerable savings on expensive lead-free solder.

Wave Soldering: A nitrogen "blanket" is used to cover the surface of the solder wave. This inert shield prevents the molten solder from coming into contact with ambient air, which dramatically reduces dross formation and improves the penetration and overall quality of the solder joints.

Semiconductor Wafer Fabrication: Across nearly every stage of semiconductor manufacturing—including photolithography, etching, annealing, and packaging—Ultra-High Purity (UHP, 99.9995% or higher) nitrogen is essential. It serves as a carrier gas, a protective atmosphere, and a purging agent to prevent even trace amounts of oxygen or moisture from contaminating the delicate wafer.

Key Technical Considerations for High-Purity Nitrogen Systems

When selecting a PSA nitrogen system for the precision-driven electronics industry, achieving a peak purity level is not enough. Decision-makers should focus on two deeper technical factors that ultimately determine final product yield and long-term operational costs:

1. Ultimate Purity Stability: Success in electronics manufacturing is measured in Parts Per Million (PPM). During the soldering process, even a momentary fluctuation in purity (a slight increase in O₂ or moisture content) can result in the scrapping of an entire batch of expensive components. Therefore, a superior system's core advantage lies not just in its ability to consistently deliver UHP-grade purity, but in its capacity to , even under the stress of fluctuating production loads.

2. Control over Trace Contaminants: Beyond oxygen, trace amounts of moisture and hydrocarbons in the gas stream are the "invisible killers" in semiconductor and high-density circuit board manufacturing. A top-tier solution must be a complete, end-to-end purification system. This requires not only a high-performance core separation material (CMS) but also a deeply optimized multi-stage air filtration and drying system, ensuring that every step, from the air intake to the nitrogen outlet, is engineered with the singular goal of achieving absolute purity.